-

fire -

Oil and chemical accidents -

Disinfections and decontamination

-

Water emergency supply

-

Pumping off (water, mud, chemicals)

-

Insect control (mosquitoes, grasshoppers, etc.)

-

Dust control

The container contains about 20 pcs. Self-sufficient extinguishers that can give off spray water and refill yourself.

It is easier and cheaper to equip and operate 60 people with 20 IDS and HD * fire extinguishers, and to use 20 fire trucks.

IDS with HD extinguishers can be operated by skilled personnel, adolescents and women after brief instruction.

Only the means of transport have to be organized on site. The payload would have to be approx. 500 kg - 1000 kg. There are wheel loaders, picups, tractors, cars with trailers, trucks and horse-drawn vehicles.

Only the means of transport have to be organized on site. The payload would have to be approx. 500 kg - 1000 kg. There are wheel loaders, picups, tractors, cars with trailers, trucks and horse-drawn vehicles.

The extinguishing performance of IDS nozzles is 11.6 L / min when the pump is fully set per IDS-P. Approx. 2000m² / min water surface, which results in the use of 20 devices about 40.000m² / min water surface which is applied simultaneously.

Container content 20 feet

The equipment is applicable to fire, oil spills, disinfection, decontamination.

-

20 extinguishing units

-

Power supply by units (light) for containers

- Technique corner with vise for easy repairs

-

3 x smallest petrol pumps

- 28 Big Bags

-

24 folding tanks

-

including one for the container roof as a washing opportunity

-

3 tanks for feeders

-

Sanitary facility for associations and minor accidents

-

Reserve extinguishing agent QF

-

1 conductor

-

5 pcs. Chainsaws with accessories

A self-sufficient deletion unit consists of:

-

1 water tank Foldable 500L or 1000L per order,

-

2 big bags before helicopter and crane transport

-

1 IDS-P and double lance with flat and spot jet for oil and chemical applications

-

1 HP * fuel pump with injector mixing 9.5 HP, on request diesel pump

-

1 HD * hose reel 100 with 2 x 50m hose lengths

-

1 HD * Injector submersible pump for tank filling, pumping out dirty water, oil and water-soluble chemicals

-

3 pairs of gloves with high cuffs and 3 simple oil resistant work gloves

-

5L reserve canister,

-

5L QF extinguishing agent canister

-

bucket

-

1 filling funnel for manual pump filling

-

1 shovel

-

1 light hoe

-

1 light ax with long handle

-

Made to order light oil barriers including air pump

-

3 persons

-

Pump man, hose man, 1 man to IDS-P

* HD = high pressure

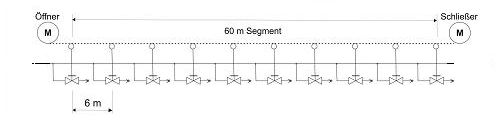

Figure 1

Figure 1

Figure 2

Figure 2  Figure 2b

Figure 2b

Figure 3

Figure 3